ACO - El futuro

de drenaje

What does ACO stand for?

ACO is an Acronym of Ahlmann Family. The family that started ACO and still owns it today

How many people does ACO employ?

Approximately 3800 employees worldwide.

When did ACO start?

1946 Josef-Severin Ahlmann (1924-2006) sets up his new company, ACO, on the site of the Carlshütte Foundry inBudelsdorf, near Rendsburg, Northern Germany. Initial products were concrete and polymer concrete drainage channels were added in the late1960s.

When did ACO become international?

1972. ACO set up a company in Switzerland, followed by France in 1976 and the United States of America in 1978. Since then the ACO Group has expanded globally and today has companies worldwide.

Why is surface drainage important?

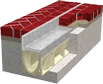

It is understood that standing water in and around facilities can cause severe structural damage. Potential problems include cracked foundations due to static water pressure buildup on the wall, settling, degradation of adjoining building materials, and freeze–thaw issues. Similarly, ponding (i.e. water collection) and hydroplaning on roads, highways, and bridges are possible safety hazards that can be avoided.

Effectively handling and transporting away rainfall during and after storms is a prime component in facility and road construction planning.

What are the different types of surface drainage?

Surface drainage can be accomplished using three different systems—catch basins, open swales, or grated trench drains. Cost comparisons have shown modular trench drains to have lower total installed costs when labor, excavation, pipework, grading etc., are taken into account.

Are modular trench drain systems expensive?

On average, pre-cast modular trench drains cost about 10 percent less to install and maintain than catch basin systems, and 20 percent less than cast-in-place trench drain systems.

What is a catch basin drainage system?

Trench drain systems employ a simple angled grade on both sides of a linear trench to move runoff into a point along the channel. Liquids are then discharged at the end of the drain into an underground pipe system or culvert. Trench drains need a shallower excavation than catch basins with extensive underground piping.

Cast-in-place systems are one type of trench drain design. This method uses extensive formwork and labor required for producing and installing the system. A form is built (usually wood) and concrete is poured around it and the form removed to leave a trench. Most cast-in-place systems are usually 8 to 12 ins in width, and possibly wider. These large widths require oversize grates, which drive up project cost dramatically.

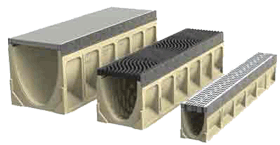

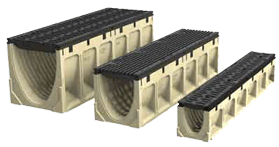

What is a modular trench drain system?

Modular trench drains are another way to produce a trench, Modular trench drain channels are typically factory manufactured and offered in meter or half-meter lengths to enable easy transport to the jobsite, on-site handling, and versatile configurations.

Modular channels usually start at 4 in. wide. These narrower widths use smaller grates, significantly reducing overall project costs. Wider systems are available if required by hydraulics or application.

Channels are aligned onsite via male/female interconnecting ends to form a continuous sloped run. Systems offer up to 40 interconnecting sloped channel depths (sizes) to create continuously sloped trenches upto 125 ft long. Neutral channels with no slope that can be inserted along runs to extend length.

What is polymer concrete?

Polymer concrete is a durable material which is resistant to road salts and common chemicals. It is made from polyester resin reinforced with mineral aggregates and fillers.

What is Fiberglass?

Fiberglass, a lightweight material made from polyester resin binder reinforced by glass matting and fibers.

What are fiberglass trench drain systems used for?

Fiberglass is used for high-capacity drainage runs in concrete slabs or where corrosion resistance is needed.

Can modular trench drains be used with harsh chemicals?

While polymer concrete and fiberglass trench drains provide effective durability in general industrial uses carrying water and basic liquids, certain chemicals or extreme temperatures require channel construction with more ‘exotic’ high-performing resins such as vinyl ester. In chemically aggressive environments, vinyl ester is specified along with grate choices that also meet the same chemical resistance standards.

For extreme high temperatures found in some processing facilities, stainless steel is the best material.

Are polymer trench drain systems weather resistant?

Polymer concrete and fiberglass both have a coefficient of expansion and contraction similar to Portland cement, and so they will expand and contract at the same rate as the encasement, minimizing buckling or pulling away from the concrete surround. They have a low rate of water absorption and will not suffer during freeze-thaw cycles.

Why are there so many different grates?

Except for the visible grate, most of the trench drain system is underground and virtually invisible. So the grate must work together with the channel to provide the right load classification performance and visual qualities.

Grate slot patterns include:

• perforated;

• slotted;

• mesh;

• decorative hole pattern

Grate materials come in a variety of different materials such as ductile iron, galvanized steel, stainless steel, non-ferrous metals, plastics and fiberglass.

Grates that comply with requirements of the Americans with Disabilities Act (ADA) of 1990 are available.

Other safety-focused grates include a ‘heelsafe’ pattern in compliance with American Society of Mechanical Engineers (ASME) A112.6.3, Floor and Trench Drains. Section 7.12, “Heel Resistant Strainers and Grates,

Grates are designed to prevent small stiletto-style heels from getting stuck, causing injury or falls. In addition, bicycle-safe grates avoid slot openings that can trap modern bicycle wheels.

What are the different Load Classes for grates?

There are a variety of different standards that partly cover the use trenches and grates in North America. There is only one global standard specifically written to measure and dictate the use of trench drain systems: EN1433. EN1433 classifies load ratings as follows -

Load class A - Residential and light pedestrian traffic

Load class B - Sidewalks and small private parking lots

Load class C - Parking lots and general commercial areas

Load class D - Trafficked sections of roads and highways

Load class E - Industrial areas, gas stations and light commercial forklifts

Load class F - Aircraft pavements, docks, heavy fork trucks and heavy wheel loads

What is ACO’s mission?

ACO creates products for water management solutions.

Global climate change is causing more frequent extreme weather events such as droughts and heavy rainfall. We develop innovative product and system solutions to weather these events.

Where is ACO USA located?

ACO USA is headquartered in Casa Grande, AZ, and has manufacturing facilities in Chardon, OH; and Casa Grande, AZ. ACO has a sales and distribution center in Fort Mill, SC

Does ACO only make trench drain products?

ACO designs and produces a variety of products:

• ACO Drain –Commercial trench drains. ACO Drain is the world leader and pioneer of the modular trench drainage. ACO commercial trench drains are used in a variety of applications from plazas to airports. ACO trench drain products have been used at many prestigious locations since 1972.

• ACO Sport – Sport field and stadium drainage systems, sandpit and curb systems, used at Olympic venues since 1972.

• ACO Infrastructure – A range of surface drainage products engineered uniquely for highways, urban roads, bridges, docks and airports.

• Aquaduct – Custom drainage solutions engineered to specific project requirements.

• ACO Environment – Liquid and solid separators and spill containment systems manufactured from corrosion-resistant materials.

• ACO Wildlife – Products which assist in saving wildlife from being killed on our roads.

• ACO Utility Duct – Surface ducting systems designed to protect cables and pipes against external influences.

• ACO Sidewalk – Detectable warning devices constructed from 14,000 PSI polymer concrete.

• Markant by ACO – Residential trench drain products designed for thelandscape, builder and DIY enthusiast.

• QuARTz by ACO -- Linear shower drain channels which allow the bathroom floor to take on a new dimension and become an integral part of the design.

Productos

Sistemas para profundidad restringida.

Los productos siguientes se pueden utilizar en una variedad de aplicaciones con requisitos especiales para la instalacion de drenaje.

Clic en esta barra para ver los productos.